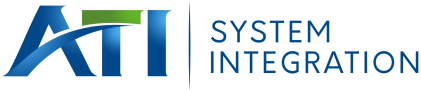

Production grain drying with automatic temperature and air control, featuring ADAPT ™

Innovative Full Process Automation: ADAPT™ revolutionizes grain drying by automating the entire process, ensuring precision and efficiency in moisture control.

Advanced Environmental Sensing: Utilizes cutting-edge environmental sensors to optimize the drying rate, eliminating the need for manual moisture sampling.

Proprietary ADAPT™ Algorithm: A unique algorithm that intelligently adjusts drying parameters based on real-time environmental data for optimal results.

Enhanced Productivity: Frees up operators from the drying process, allowing them to focus on other critical post-harvest tasks.

Retrofit Compatibility: Offers a monitor-only version, making ADAPT™ suitable for retrofitting existing grain dryers.

Versatile Deployment: Designed to be flexible, ADAPT™ can be deployed on any size or style of grain dryer, catering to a wide range of agricultural needs.

Real-Time and Historical Data Analysis: Provides comprehensive monitoring with real-time and historical data trending for informed decision-making.

Remote Monitoring and Alerts: Stay informed with remote alarm and progress notifications via email and SMS, ensuring constant connectivity and control.

Energy Efficiency: Aims to significantly reduce energy consumption, aligning with sustainable farming practices.

Yield Improvement: By optimizing the drying process, ADAPT™ aims to increase yield, ensuring maximum productivity and profitability.

Automatic Temperature and Air Control: Features state-of-the-art temperature and air control for consistent and reliable grain drying.

User-Friendly Interface: Easy-to-use interface for seamless operation and monitoring of the drying process.

Eco-Friendly Solution: Designed with environmental sustainability in mind, reducing carbon footprint in the agricultural sector.

Bulk product weighing, packaging and transport

- Bulk bags and boxes used for production grain processing

Power plant systems control

- Coal burning facility monitoring and control

Manufacturing

- Commercial window manufacturing equipment programming

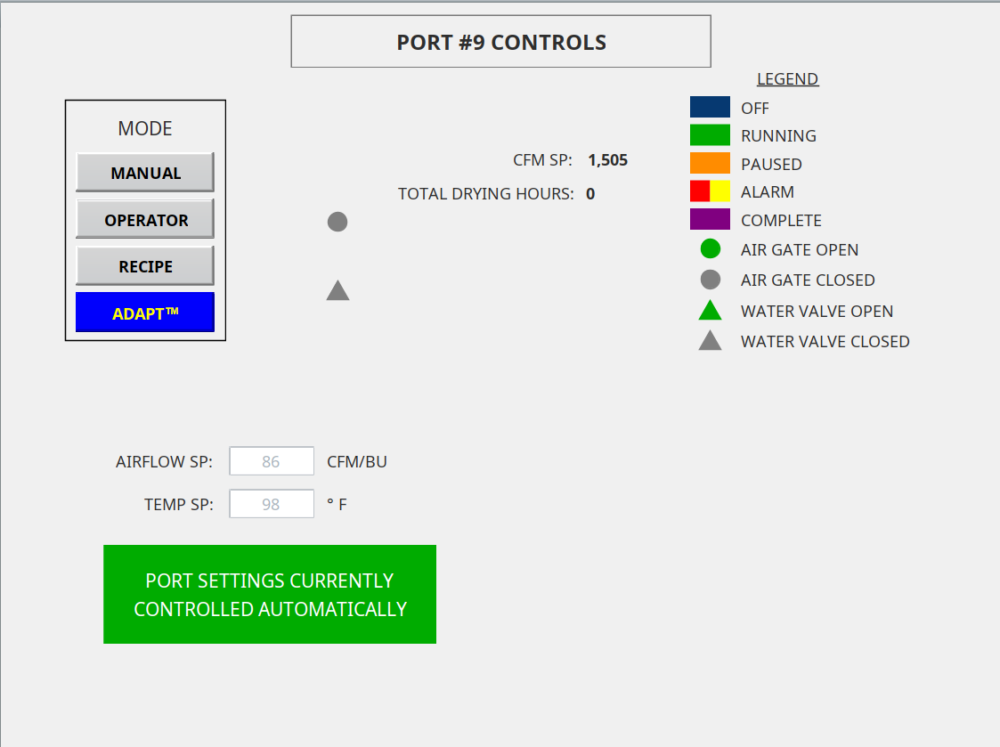

Agriculture processing

- Full plant automation and integration

Fully Automated Conditioning Line

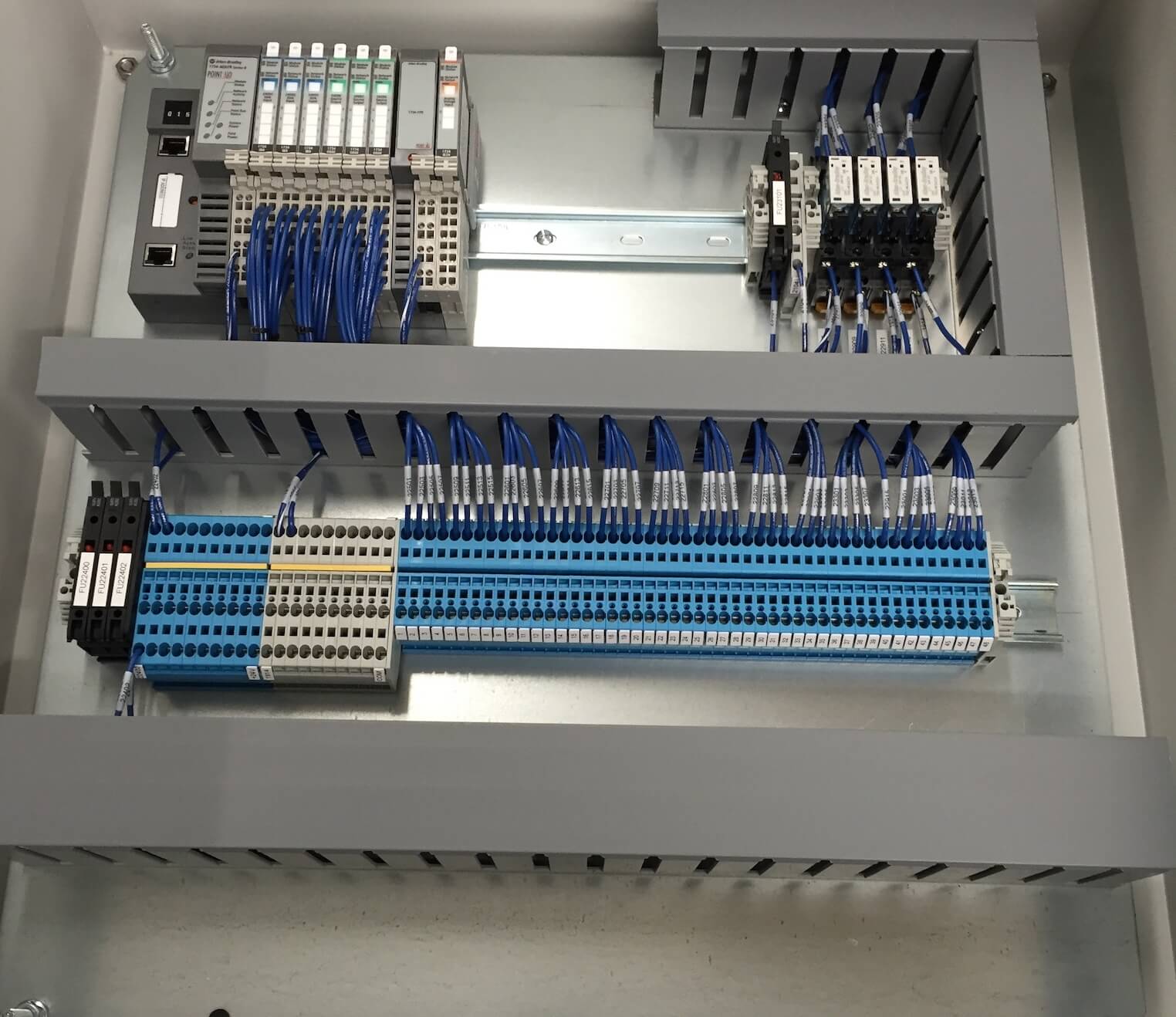

UL listed panels

Worldwide Project Locations

Iowa

- Ankeny

- Ames

- Des Moines

- Pella

- Marshalltown

- Toledo

- Dysart

- Durant

- Hedrick

- Ottumwa

- Mt. Pleasant

- Renwick

- Marengo

- Johnston

- Marcus

- Cherokee

- Algona

- Washington

Illinois

- Woodhull

- Atkinson

- Utica

- Litchfield

- St. Francisville

- St. Joseph

- Le Roy

- Good Hope

Indiana

- Tipton

- Plymouth

- Rushville

Ohio

- Grand Rapids

North Dakota

- Wahpeton

Minnesota

- Jackson

Missouri

- Princeville

Nebraska

- York

- Doniphan

- Phillips

California

- Woodland

- College City

Hawaii

- Oahu

- Kauai

Washington

- Connell

Oregon

- Hermiston

Texas

- Eagle Lake

- Danbury

Thailand

- Khon Kaen

- Chai Nat

Philippines

Puerto Rico

Mexico

- Puerto Vallarta

Guatemala

- Jalapa